Company G is a local intimate apparel manufacturer with factories in Mainland China and Southeast Asia. As the main supplier for big brands of intimate apparel, the company keeps its research, product design and product development centers in Hong Kong, instead of moving outside like many other manufacturers in the industry. It values professional talents, especially with expertise in intimate apparel fitting, product development and technology innovation. It has established a mature tutor system for long-term technician training and also awards scholarships to outstanding students in related areas of leading universities so as to cultivate potential young talents. One difficulty to operate product development center in Hong Kong is to hire qualified sewing workers. To adapt to the requirements for fast and large quantity supply, the company has used SAP to manage the operation from raw material, product design and development to manufacturing and product delivery.

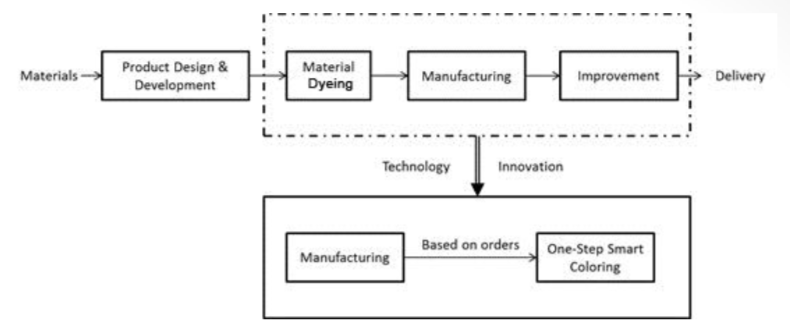

To improve the processing for its production, it has invested funds and talents on technology innovation. Its research team has created equipment for undergarments’ one-step smart coloring, saving close to 90% of water, chemicals, energy and time. With this new equipment, the company can realize the flexibility to color intimate apparels without minimum order quantity in a sustainable way. This new concept of colouration also improves the dyeing process for the whole industry. The production process flowchart is illustrated as follows:

Usually, in the production process of the bra, material dyeing includes pads, metals, plastics, and elastic, different materials may have problems in color shading, size and function after manufacturing, so some improvements should be done before final product delivery. With this innovative equipment, all the intimate apparels can be garment-dyed as a final product, and that would allow more agile product supply, more flexible product coloring and more sustainable manufacturing.

Company G shows a successful model for technology innovation in traditional textile and clothing manufacturing, which not only improves production efficiency and flexibility but also upgrades the traditional polluting process to meet stringent environmental policy.